I really like my indoor grow light basement setup. With the average first frost in the region to be around 10/19, I’ve been revisiting the setup and considering what I’m going to be keeping inside overwinter. And as I pondered the setup, I thought about how much easier things would be if I had a hose connected down there. And as it just so happens, it’s only about 10 feet away from the main water line.

This portion of the basement is where the laundry machines are hooked up, as well as a utility sink. The lines split off from here, feeding two external spigots, and there’s the whole house filter, the water heater, and the general myriad of lines for sinks and bathrooms. To me, the mess of copper looks like the depths of some steampunk facility.

In the chaos, the main water line passes through two spigots. The spigots are closed, with a central spigot which bypasses them–open. It looks like a setup for a water softener. I don’t know if one was ever installed, because the water here doesn’t need conditioning, but maybe it once did. Who knows? Regardless their intended purpose, it gave me an idea–could I just simply connect a hose to one of those spigots?

As it turns out, no. The threads were much too wide for a standard garden hose. But surely there’s an adapter, right?

Armed with this logic, I was off to Lowe’s to look at copper fittings. I quickly discovered that the maximum copper fitting size was 1 inch. Recalling how wide the spigot was, I gambled and bought a 1 inch to 3/4 inch reducer. I hurried home to see the fruition of my project, but soon determined that 1 inch was too small. Curious, why would they not make a copper fitting big enough to fit a copper spigot?

So I went to Home Depot instead. But I ran into the same problem here. None of the connectors were big enough. Staring blankly at the wall of copper, a store employee took pity on me and offered to help. I explained my plight, and he informed me that they don’t carry anything in copper bigger than one inch, but he could get me the needed size connectors in PVC.

I really wanted copper, but this project wasn’t for any high-impact application, so as long as it would work at all, I could live with PVC. So, with two PVC adapters and a brass threaded hose connector, I headed back home. I then attempted to attach the PVC to the spigot, and…it was too big. What the hell? I went up one standard size from one inch: 1-1/4. Why wouldn’t that fit? And it was only slightly too big, like 1/16 of an inch. Was this spigot metric?

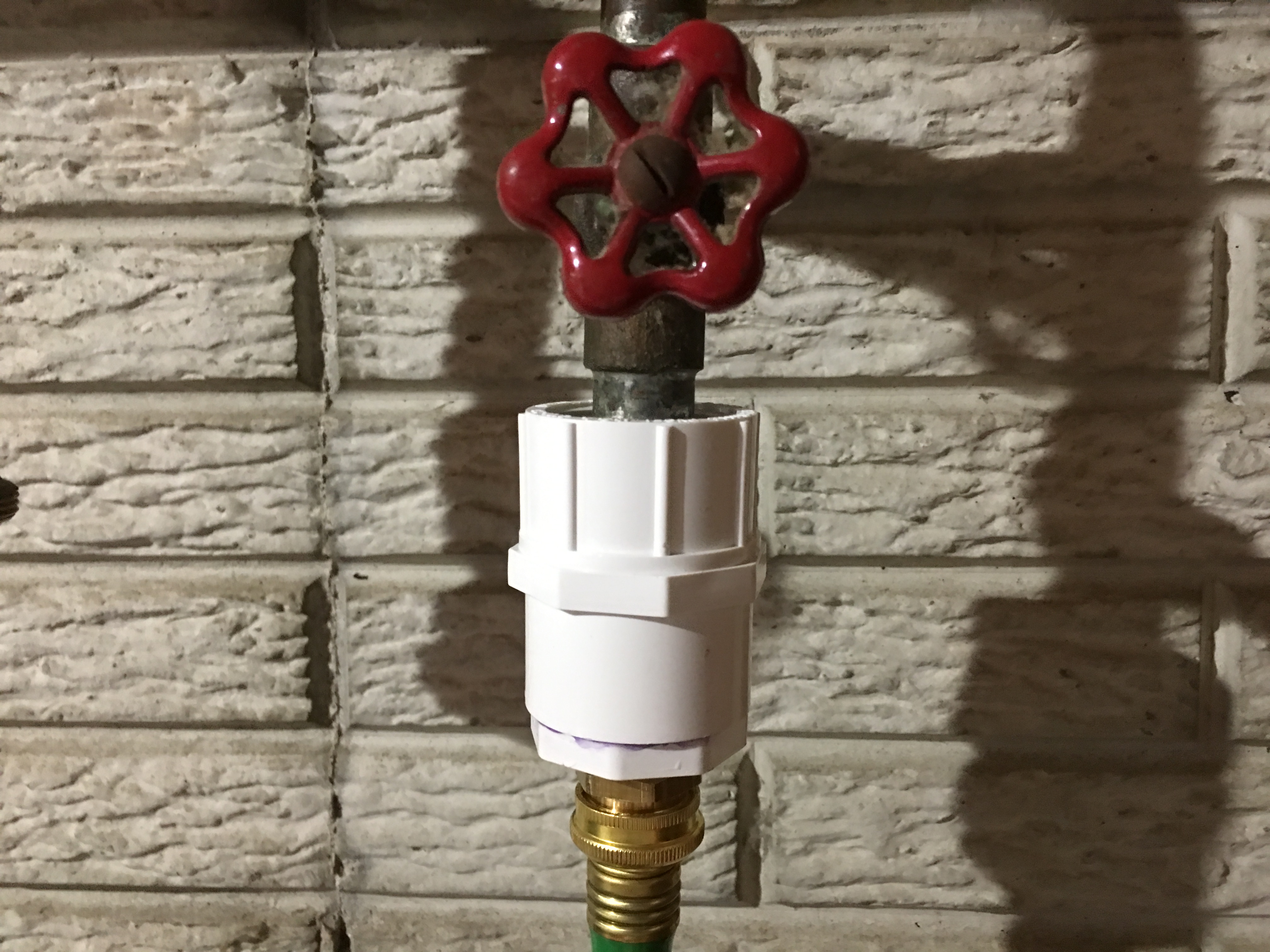

I stewed over this dilemma, and concluded that I would experiment. So I wrapped the threads in a bunch of Teflon tape to fill the gap, cranked the PVC down, and filled the resultant void (due to the depth of the PVC threads) with a waterproofing adhesive. I let it cure for 24 hours. Maybe that would be sufficient.

It wasn’t. Even though I didn’t turn the water on very high, it was still the main water line, and the pressure was too great. The joint failed with a pop and I had to scurry over and shut the spigot. Curses.

Okay, experiment 2. I removed all the adhesive and Teflon. This time, I was armed with self-fusing silicone tape–something designed to seal high-pressure pipes (which I bought on a whim while I was returning the first batch of connectors). I wrapped the spigot threads with enough tape that it became an effort to crank down the PVC connector. This stuff was supposed to adhere to any surface and be completely waterproof. I let it sit for a bit, but it didn’t have any cure time so that hardly seemed to matter. This time, I decided to test it without any sealant, since the sealant itself wouldn’t hold the pressure anyway. I turned the water on, higher than I had turned it on with my last attempts.

And…it held. Huh, maybe this silicone tape is magic after all. I let the hose stay pressurized for a time, then shut it off and de-pressurized the line. I refilled the gap with sealant, figuring it might still help by adding support. And so far, it’s working as I had hoped. I’m uncertain of this solution’s permanence, and somewhat unhappy with the inelegant and hacked solution, but time will tell. And if it doesn’t hold up, then I’ll simply splice into the wash machine line instead. I know I can get proper connectors for that at least.

Still, the irritation lingered, and I searched for an explanation. Curiously, pipe fittings are not nearly as standard as I had thought, and the actual measurements are approximations which have changed over time. So whenever this spigot was installed, for whatever connection it was intended, is no longer a current standard. Sheesh. Maybe one day I’ll try soldering in a nice ball valve threaded for a garden hose, but for now, I don’t want to risk compromising the main water line and having to call in a professional.

Why the hell aren’t pipes all standard sizes? Another homeowner lesson.

–Simon